|

Henan Zhongke Engineering & Technology Co.,Ltd.

|

Factory direct Supply Sand dryer

| Price: | 10000.0 USD |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Sand dryer is a kind of processing large amounts of material drying machine. Due to the reliable operation, good adaptability, high yield,widely used

Sand dryer application

Sand dryer is a kind of processing large amounts of material drying machine. Due to the reliable operation, good adaptability, high yield, widely used in metallurgy, building materials, food, chemicals, coal, medicine and other materials. Sand dryer belong to rotating cylinder dryer. Commonly adapted to the powder and granular materials, can also use the mixing material approach drying viscous paste-like material or high water content materials. Especially dry sand, TaiDa sand dryer effect is excellent. Sand dryer with advantages of great capacity of production, wide application, small flow resistance, convenient operation, etc.

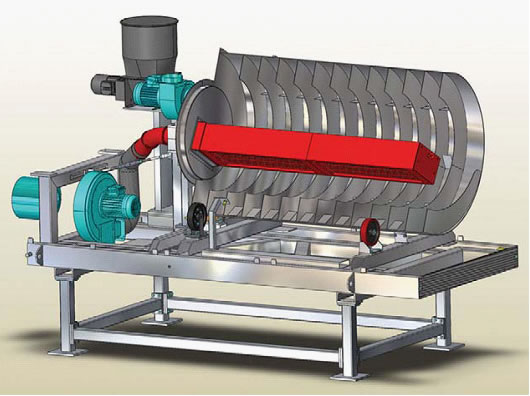

Sand dryer structure

1.the cylinder 2.the front roller ring 3.after the roller ring 4.gear 5.gear roller 6.drag roller 7.small gear 8.the discharging part 9.board 10.speed reducer 11.electric machinery 12.hot air duct 13.feed chute 14.furnace body and other components, and according to the user' needs to design gas furnace, the combustion chamber or the elevator, conveyor belt, quantitative feeder, cyclone dust collector, a draught fan, etc.

Sand dryer working principle

Sand sent to the hopper by the belt conveyer and bucket elevator, and then through the hopper feeder into the feeding pipe, thereby entering the feeding end. The feeding pipe inclination is greater than the natural angle of materials, so that material flows into the sand dryer.Dryer cylinder is a rotating cylinder that have a certain inclination with horizontal line. Material from the high-end to join, heat carrier from the low-end entry, countercurrent contact with material, also have heat carrier and material flow into the cylinder together. With the rotating cylinder materials by gravity run to the lower end. Wet material in the cylinder body to move forward, heat by heat carrier directly or indirectly, so that the wet material to be dried, then at the discharge end through a belt or a screw conveyor send out. In sand dryer inner wall of the cylinder is provided with a copy board. Its role is to bring up material then down, increasing the contract surface of material and gas flow, in order to improve the drying rate and promote material progress. Heat carrier are generally divided into hot air, flue gas. Heat carrier through the dryer, then the material in the gas was collected by cyclone dust collector. If need to further reduce the exhaust gas dust content,also should dust by the bag dust collector.

High density rotary dryer parameters

Model | Inside Dia. | Length | Gradient | Rotate Speed | Power | Capacity | Weight |

ZT-1.2X6.0/8 | 1.2 | 6/8 | 5.0 | 5.8 | 5.5 | 8-12 | 9380/10200 |

ZT-1.5X12/15 | 1.5 | 12/15 | 5.0 | 4.8 | 15 | 12-16 | 16450/18240 |

ZT-1.8X12/14 | 1.8 | 12/14 | 5.0 | 4.5 | 18.5 | 18-20 | 20000/2100 |

ZT-2.2X12/14 | 2.2 | 12/14 | 5.0 | 4.3 | 22 | 22-28 | 37100/38830 |

ZT-2.4X14 | 2.4 | 14 | 4.0 | 3.78 | 30 | 30-35 | 50700 |

ZT-2.4X18 | 2.4 | 18 | 4.0 | 3.0 | 37 | 35-40 | 54000 |

ZT-2.4X22 | 2.4 | 22 | 3.0 | 3.0 | 45 | 38-42 | 57000 |

ZT-2.8X20 | 2.8 | 20 | 4.0 | 3.7 | 40 | 45-55 | 71000/75000 |

ZT-3.0X22/25 | 3.0 | 22/25 | 4.0 | 3.2 | 75 | 58-70 | 88000/95000 |

ZT-3.2X25 | 3.2 | 25 | 4.0 | 3.0 | 110 | 75-90 | 166000 |

ZT-3.6X25 | 3.6 | 25 | 4.0 | 2.7 | 132 | 95-110 | 188000 |

About us:

Henan Zhongke Engineering & Technology Co., Ltd. since its inception has been to customers to provide quality and efficient service. Production jaw crusher, counter type crusher, hammer crusher, vibrating screen set of sand production line, aeratedconcrete equipment deep customer satisfaction. Our caring service, careful manufacture, price satisfaction, let customer feel rest assured . "Customer oriented", provide overall service for the customer; "to serve as the core", for customers to create the most valuable products. "Take the quality as the center", a full range of services to customers.